| Price: | $70.00/pieces 1-9 pieces |

| Standard Packaging: | Customizable packaging |

|

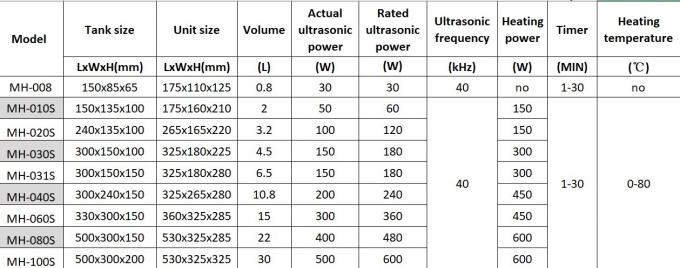

Product parameters:

|

|

|

|

|

||||

|

Model:

|

MH-020S

|

|

|

|

||||

|

Inner tank size:

|

240X135X100mm

|

|

|

|

||||

|

Product size:

|

265X160X225mm

|

|

|

|

||||

|

Packing size:

|

340X245X300mm

|

|

|

|

||||

|

Power:

|

110~240v

|

|

|

|

||||

|

Working Frequency:

|

40khz(customizable 28Khz)

|

|

|

|

||||

|

Capacity:

|

3.2L

|

|

|

|

||||

|

Packing in carton:

|

1 pieces

|

|

|

|

||||

|

Net weight:

|

3.2Kg

|

|

|

|

||||

|

Gross weight:

|

3.7Kg

|

|

|

|

||||

|

Logo:

|

Meihong/Your Logo

|

|

|

|

||||

|

OEM/ODM:

|

Accepted

|

|

|

|

||||

| Price: | $70.00/pieces 1-9 pieces |

| Standard Packaging: | Customizable packaging |

|

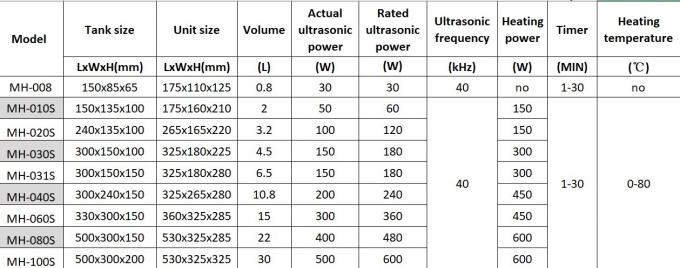

Product parameters:

|

|

|

|

|

||||

|

Model:

|

MH-020S

|

|

|

|

||||

|

Inner tank size:

|

240X135X100mm

|

|

|

|

||||

|

Product size:

|

265X160X225mm

|

|

|

|

||||

|

Packing size:

|

340X245X300mm

|

|

|

|

||||

|

Power:

|

110~240v

|

|

|

|

||||

|

Working Frequency:

|

40khz(customizable 28Khz)

|

|

|

|

||||

|

Capacity:

|

3.2L

|

|

|

|

||||

|

Packing in carton:

|

1 pieces

|

|

|

|

||||

|

Net weight:

|

3.2Kg

|

|

|

|

||||

|

Gross weight:

|

3.7Kg

|

|

|

|

||||

|

Logo:

|

Meihong/Your Logo

|

|

|

|

||||

|

OEM/ODM:

|

Accepted

|

|

|

|

||||